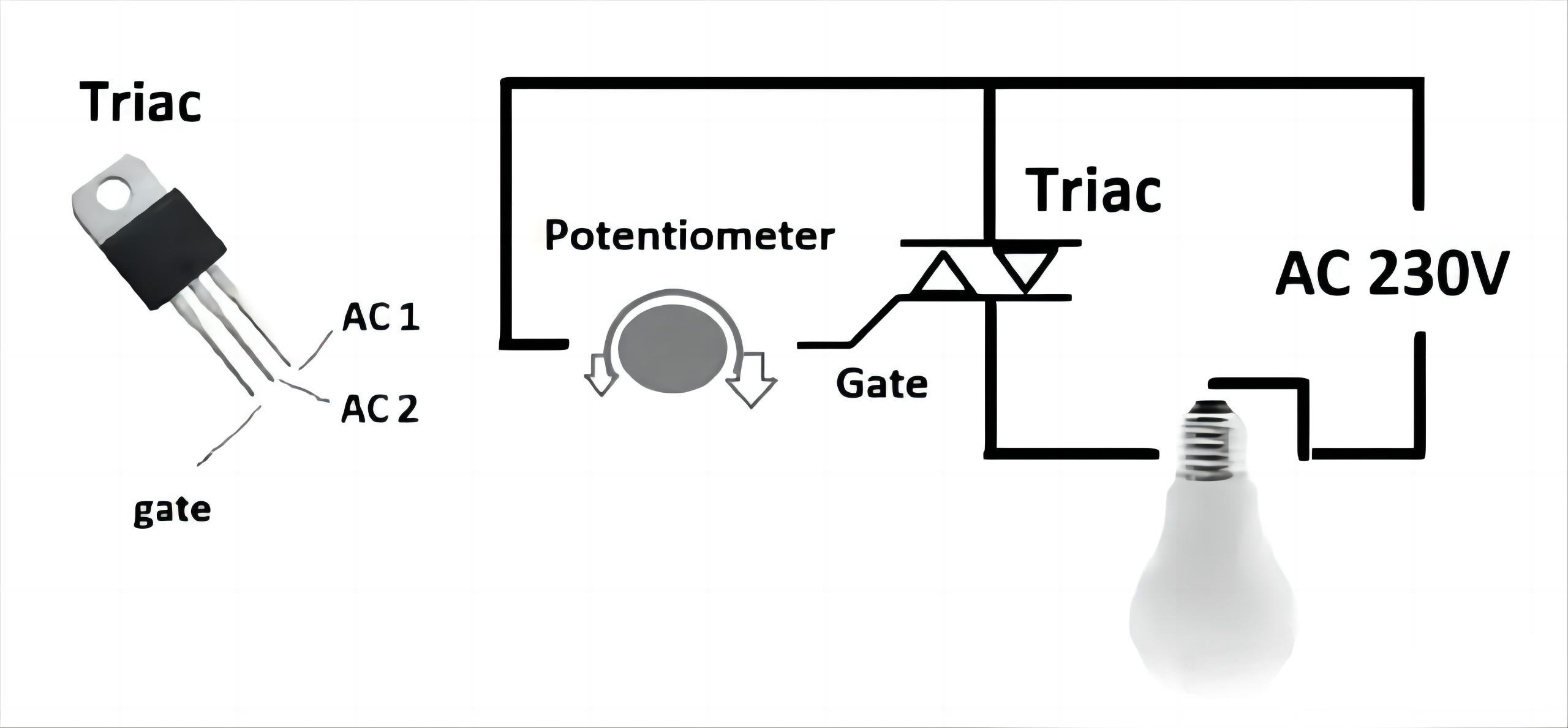

Triac dimming

This method was developed in the 1970s and has been the most commonly used dimming technique for decades. It does this by changing the waveform turns on, thereby changing the amount of current or power flowing to the light.

This common dimming method uses thyristor components to control the brightness of the light, and adjusts the light by controlling the on and off of the current. When the thyristor device is forward biased, current can pass through and the brightness of the light increases. When the thyristor device is reverse biased, the current cannot pass through and the brightness of the light decreases.

The advantages of Triac dimming are large dimming range, good dimming effect, and high dimming stability. However, the disadvantages are also obvious. The thyristor destroys the waveform of the sine wave, thereby reducing the power factor and the conduction angle. The smaller the value, the worse the power factor.

Non-sinusoidal waveforms increase the harmonic coefficient, which easily produces serious interference signals in the circuit. Phase dimming is prone to instability at low loads. For this reason, a bleeder resistor must be added, and the bleeder resistor must consume at least 1-2W power. In addition, when the ordinary thyristor dimming circuit is output to the LED driver power supply, the LC filter at the input end will cause the thyristor to oscillate, which will produce audio noise and flicker at the LED power supply end.

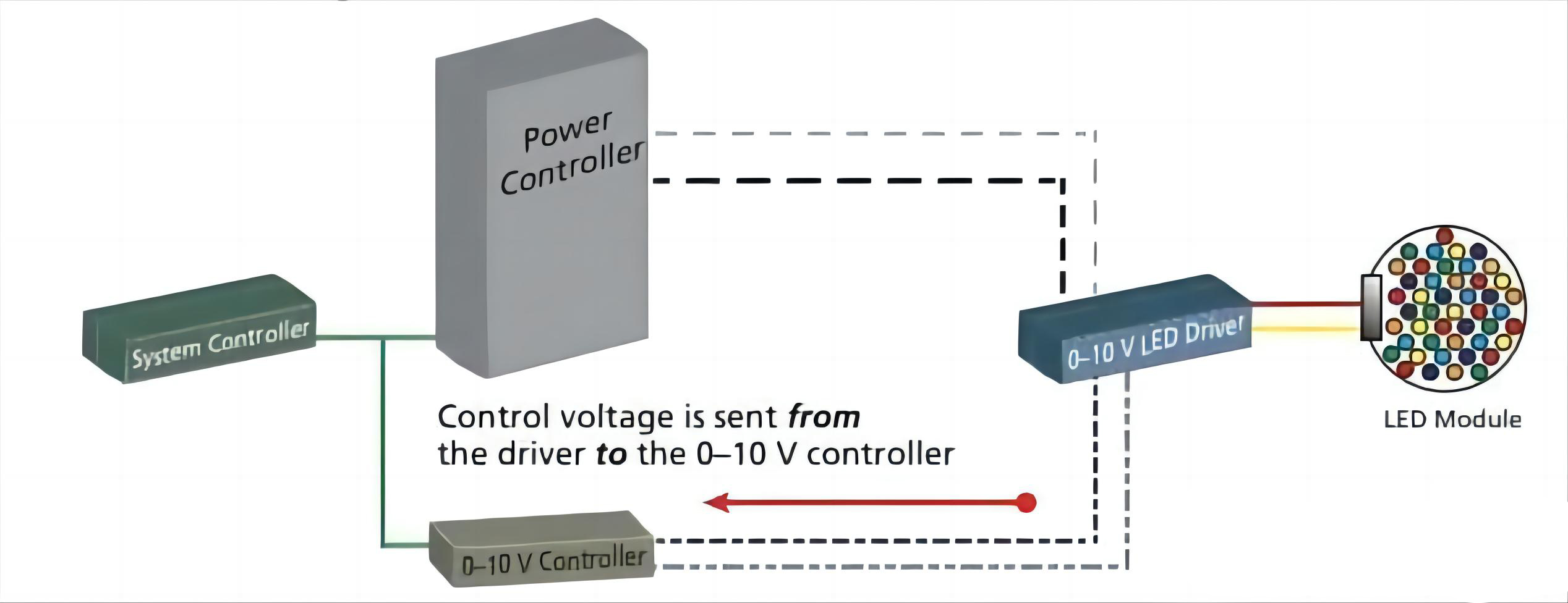

0-10V dimming

0-10V dimming technology is an analog signal dimming technology that changes the output current of the power supply by changing the voltage of 0-10V, thereby adjusting the brightness of the light. This technology has a wide range of applications, including home lighting, stage lighting and commercial lighting, as it allows for easy and precise control of lighting and infinitely adjustable loads.

Its application is mainly aimed at the control of a single loop, and cannot independently control a certain light in the loop. The advantages of this technology are simple dimming application, high precision, good compatibility, and high cost performance. The disadvantage is that it is necessary to add signal lines. If the signal lines are too long, there will be a voltage drop, and it cannot be addressed in the dimming system. Convenient for centralized management.

There are two standards for 0/1-10V dimming, which are incompatible with each other. The difference is the control voltage: generating or carrying the control voltage. In other words, the 0-10V control type is a "current sink" or "current source".

These standards are:

(1) IES Standard 60929 Appendix E

The standard uses "current sinks", originally used for dimmable fluorescent tubes, but more recently for LED transformers. "Current sinking" is when the controlled device supplies voltage to the controller, but the controller reduces the voltage back to the fixture. In this standard, light reaches a maximum value at 10 V and a minimum value if the recovery voltage is below 1 V.

(2) Standard ESTA E1.3

This standard is used to dim theater lighting. The controller supplies low voltage to the controlled device in "current source" control. The controlled device adjusts the lighting intensity according to the voltage, adjusting to maximum intensity at 10 V and to minimum intensity at 0 V.

So there will be compatibility issues. If the dimmer sends a 5V signal, the result may not be 50% of the original luminous intensity, but 30% or even 80%.

0-10V vs 1-10V

The 0-10V dimmer has a built-in on/off switch, but the 1-10V does not, so the light cannot be turned off completely. Connecting a 0-10V dimmer to a 1-10V transformer will cause problems such as light flickering, and the LED light will not turn off completely until the power is disconnected.

Triac dimming vs 0/1-10V LED dimming

Triac dimming and 0/1-10V dimming are two different technologies used to adjust LED brightness. They are often compared because both use low voltages to drive LEDs.

The working principle of thyristor dimming is to quickly turn the power on and off, while the working principle of 0-10V dimming is to control the voltage of the LED, so thyristor dimming is more energy-saving than 0-10V dimming. This is because the thyristor does not stay on when dimmed, so it consumes less energy, while the 0/1-10V dimmer uses a resistor to adjust the current of the LED, so part of the current is lost to heat.